DYNAMO’S CORPORATE SUSTAINABILITY PLAN

The level of carbon dioxide in the atmosphere has exceeded the highest recorded values. Today, we are getting warning signals from nature, upon which we depend for our survival. Targeting a reduction in Dynamo’s carbon footprint, its corporate sustainability plan has been constructed around these three items: Eco-friendly Products, “Green Plant” Principles and Green Materials.

ECO-FRIENDLY PRODUCTS

At Dynamo, we have been implementing eco-friendly technologies for our manufacturing processes since 2013. With our investments in both new fabrics and eco-friendly dyeing techniques, our goal is to produce the best quality textile without creating a destructive effect on the environment. Our eco-friendly dyeing techniques and the fabrics we have recently added to our portfolio allow us to manufacture products that meet the standards of both the aesthetic and the technical quality that are expected of our industry.

Eco-friendly Product Group 1

Indy, N-Vaga, Besh

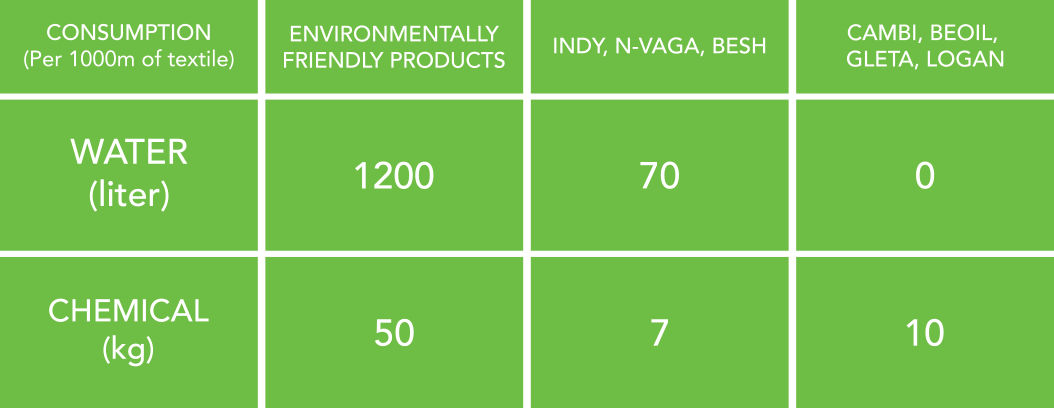

The most important aspect of this product group, which includes the textile types Indy, N-Vaga, and Besh, is that they require less water consumption during the production process. The dyeing agent is applied to the textile in the form of a foam during the production process, which results in the use of 90 percent less water compared to the reactive dyeing process.

Eco-friendly Product Group 2

Cambi, Beoil, Gleta, Logan

When it comes to water savings, Cambi, Beoil, Gleta, and Logan are types of textile that take it one step further. Water consumption is reduced to a minimum, thanks to the specially-designed coating process used in the production of these textiles.

“GREEN PLANT” PRINCIPLES

The only way to achieve more sustainability is to operate a production facility according to these principles. Since 2014, Dynamo has been investing in its production facility to bring about more sustainable production processes. In order to reduce the amount of raw material waste, recycling and recovery systems have been implemented at the facility. Thanks to these systems, Dynamo products are being processed in an eco-friendlier way. The following recycling and water purification systems are being used in Dynamo’s production facility:

Hot Water Recovery System: Prior to the implementation of the hot water recovery system, the annual water requirement for Dynamo was 44 tons, which has now been reduced to 41 tons. Some of the hot water used to power the mill turbines during the production process are provided by this recovery system. This system has also reduced energy consumption.

Heat recovery system for stenters: The heat recovery system for needle exhaust utilized in the drawer machines provides a 20 percent savings in the natural gas consumption of machinery in the production facility. Thanks to this system, the monthly gas consumption of Dynamo has been reduced from 98,000 Nm3 to 85,000 Nm3.

Wastewater Purification System: The wastewater purification system in Dynamo’s production facility is a biological purification system that purifies water by a certain extent, thus reducing the chances of harm to the environment. Although its economic cost is higher than that of other systems, when successfully installed this system performs with 95 percent efficiency. In line with the company’s environmental policies, Dynamo uses very small amounts of chemicals in its production facility. Chemicals are only used for two production phases: neutralization and mud dehydration.

Cooling Water Recovery System: The cooling water recovery system transports the cooling water from the facility to a soft water storage depot. Due to this system, daily water consumption has been decreased by up to 250 m3 .

WHAT WE HAVE DONE

Certifications and Standards

1997

Started Oeko-Tex Standard 100 certification

2015

Started Better Cotton Platform membership

2019

Started Higg Index FEM/2018 self-assessment and verification

2019

Started GOTS, GRS, OCS, RCS certification

2020

Started SLCP self-assessment and verification

2020

Started Sedex Smeta 4 Pillar audits.

2020

Started ZDHC WasteWater Reporting on Gateway

2022

Started Cotton Trust Protocol membership

Dynamo Pillars

- Employee well-being and talent development

- Sustainable Raw Materials

- Dynamo Code of Conduct

- Technical Qualitiy

- Ethical Manufacturing

- Traceability / Transperancy

Technical Development

1997 : ETP

Starting from establishment of Dynamo Mill, we have always proceed with ways in sustainability. Our Biological ETP has started processing as our mill which kept our discharged water quality higher the Legal Requirements and with compliance with the International Standards, which is now ZDHC.

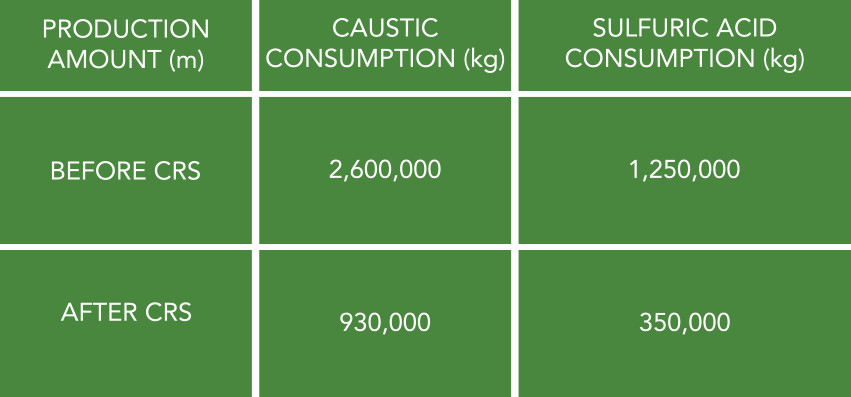

2014: Caustic Retrieval

When, the Caustic Retrieval Plant taken into process, 50% of the caustic used is regained and this also caused a 35% reduction in the acid used in the ETP for neturalization.

2021: Machinery

With the improvements and renewal in the machinery, the water consuption is decreased by 30% which reinforced our footsteps through sustainability.

Expressing fashion with cotton and natural blends offering trendsetting collections since 1991

« Be Simple, Act Natural, Feel Free »

From the beginning, Dynamo has always prioritized both customer and employee satisfaction. The company’s 200 contract employees, high-quality production capacity, investments in technological infrastructure, and effective supply chain management, have enabled the company to sustain its success.

Quality, innovation, flexibility, and a strong sense of responsibility to its customers…

WHAT WE ARE DOING

Recent Developments:

2023: Waste Water Recovery Plant

Our Waste Water Recovery Plant is in installation process has been installed and control testings are running by November 2023.

2023: Carbon Footprint Consultation and Software

We are starting to have consulting and to use a software for measuring our emissions and Carbon Footprint.

2023: Integrated Management Systems

We have started building Integrated Management Systems, ISO 9001, ISO 14001, ISO 27001 and ISO 50001 and will be finalized by early 2024.

2023: Online Chemical Management

We are measuring our ZDHC MRSL Compliance on ZDHC Gateway InCheck module via CleanChain software

FACILITY OPERATED IN RESPONSIBILITY

- Ethical Production

- Transparent

- Traceable

- Circular

WE HAVE PRIORITIZED 5 SDGS, WHICH WE BELIEVE WE HAVE THE GREATEST LEVERAGE AND POWER TO CONTRIBUTE.

WHAT WE WILL DO

Commitments

Sustainable Input

Less conventional, more Sustainable materials

- Regenerative Cotton

- Good Earth Cotton

- Recycled Cotton

Technical Input

Easy Wear&Easy Care fabric with technical material and finishing./p>

Supply Chain Management

Local, reliable and sustainable sourcing with;

- Certifications

- Audits

- Standards

Renewable Energy

Solar and Wind Power projects for Electricity

Renewable Energy Contracts

Life Cyle Assessment

Unique calculation of our environmental impact.

What we focus on sustainability?

- Water Usage

- Waste Reduction and Management

- Chemical Use

- Energy and Carbon

- Responsible Materials

- Labour Rights

- Supply Chain Management

- Health and Safety

- Technical Quality